Tool Room Manager

Central database for all HAIMER i4.0 machines

The HAIMER Tool Room Manager (TRM) is the central database for all HAIMER i4.0 machines and the tool assemblies used. It analyzes, monitors and documents the processes in the tool presetting room and tracks compliance with the specified tolerances. The digitisation of HAIMER i4.0 machines implemented in the TRM reduces downtime and increases the productivity of the entire plant.

Optimized workflow in a continuous tool room

- Starting the shrink process on the Power Clamp i4.0 device by scanning the unique ID on the tool holder

- Guided adjustment of correction allowance and real-time monitoring of the presetting length

- Automatic coil adjustment with subsequent shrinking process

- Reporting of shrinking results to TRM with success review and documentation of the operation (e. g., number of shrinking cycles)

- Scanning the unique ID as the trigger for the balancing process on the Tool Dynamic i4.0 balancing machine

- Automatic transfer of results, including maximum permitted rotational speed, to the TRM after completion of balancing

- Last but not least: Fully automatic presetting on the Microset i4.0 device with results sent to TRM and clear documentation in the job history

Highlights

- 100% tracking of all setup actions in the presetting area

- Live connectivity with job management for all i4.0 machines

- Alert management when defined tolerances are exceeded

- Automatic transfer of results for all processes and jobs with unique time stamp and user verification

- Success review and documentation of all processes using a clear traffic light system

- Predictive maintenance: notification to check the status of the mount if specified parameters are exceeded

- Constant availability of a wide variety of (setup) information in the TRM database

Software features

Unique features for greater productivity

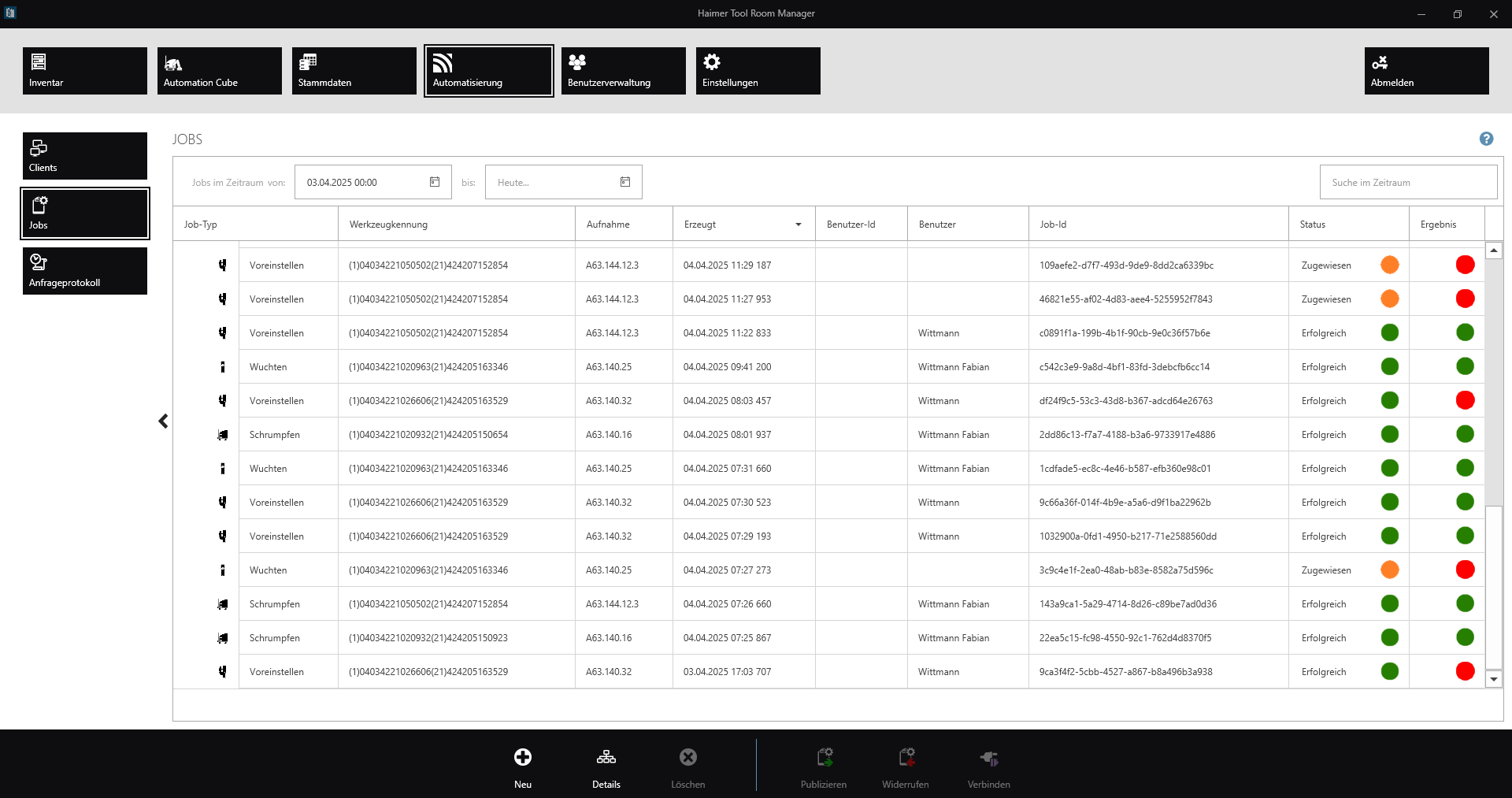

The TRM offers an intuitive job history. A traffic light system provides information about the degree of success of the i4.0 shrink, balance, and preset processes carried out with the respective complete tools used. User verification and time stamps serve to clearly document the jobs.

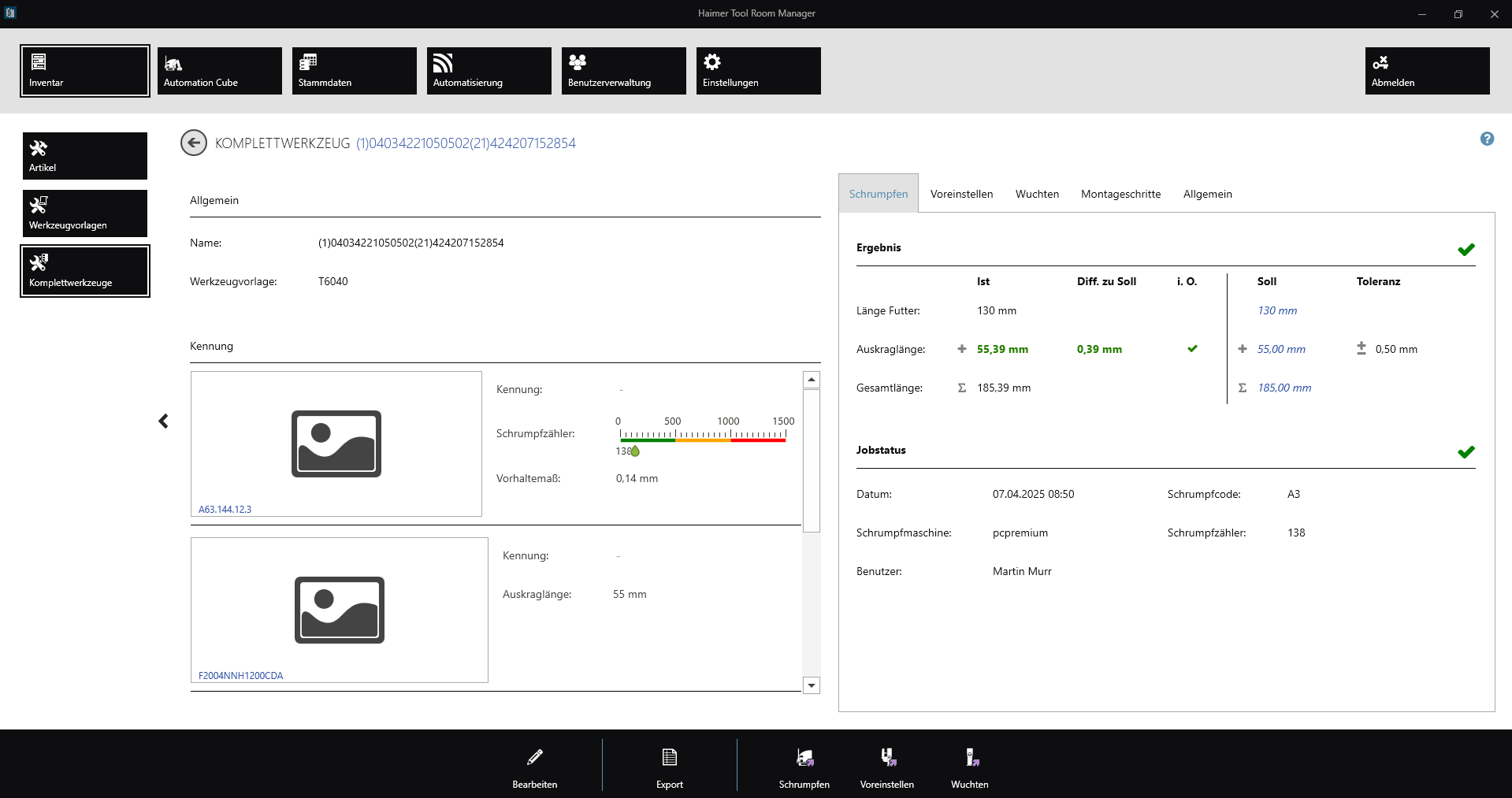

Live connectivity with HAIMER i4.0 machines allows process results and status information for the complete tools used to be accessed at any time. An integrated warning management system ensures compliance with defined tolerances. The shrinkage counter displays the current and recommended number of shrinkage cycles.

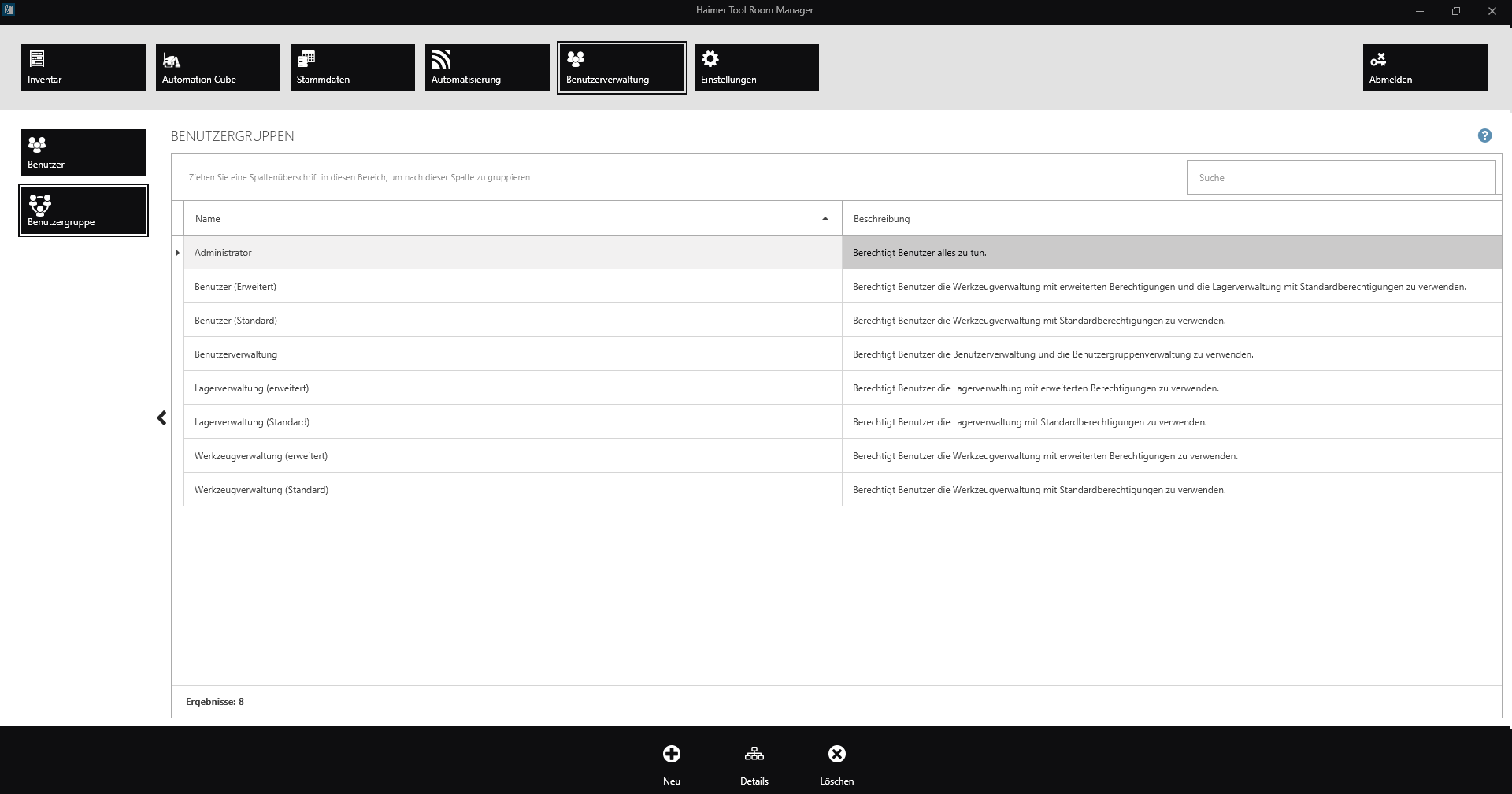

TRM includes straightforward authorization management. User groups can be easily created and assigned individual, predefined permissions. When a user is created, they are assigned to a unique user group.

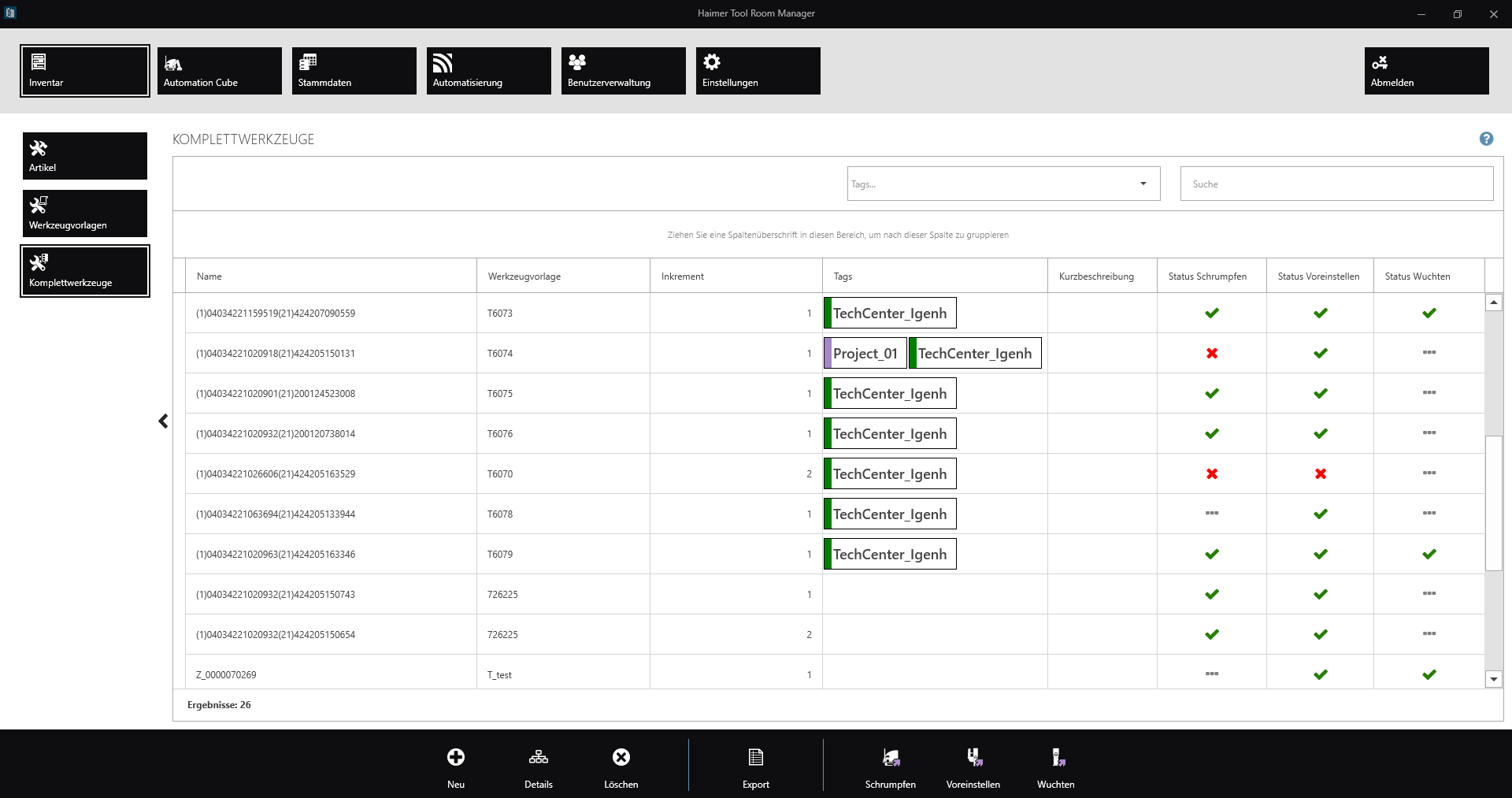

The overview of the complete tools used provides information about their success status in recent jobs on HAIMER i4.0 machines. Furthermore, individual tags can be attached to each tool combination in order to clearly identify, for example, locations of use or project affiliations.

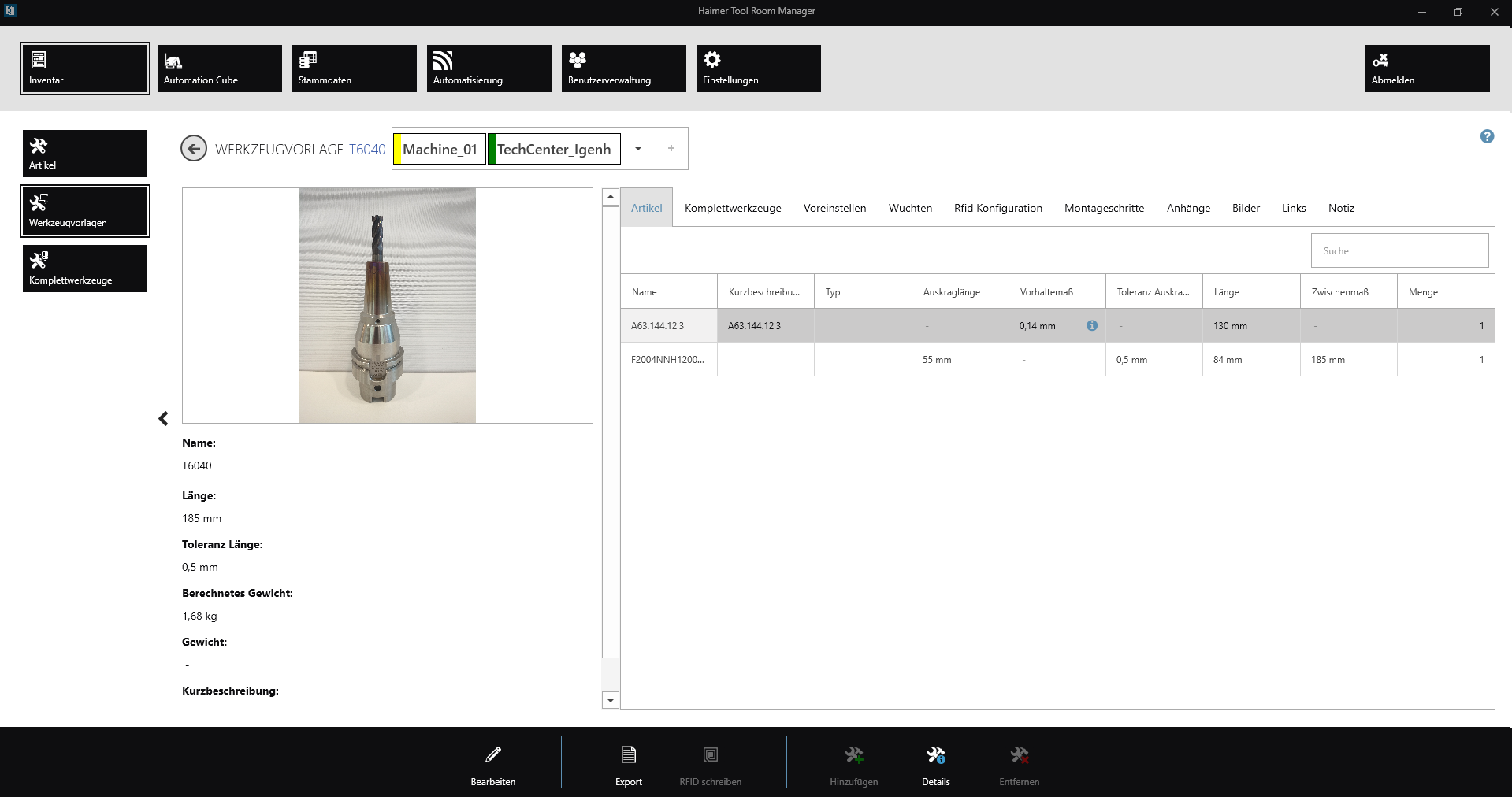

TRM offers the option of creating digital tool templates that are regularly required for recurring projects, for example. Detailed information on toolholder and tool can be accessed in the template, and images, drawings and other attachments can be stored. Furthermore, the usage history of the complete tool can be accessed.

The tool management concept

Complete tool management solution: HAIMER Tool Management

HAIMER's workbenches and modules are based on specific solutions that have been developed and refined over many years of in-house production. The entire work area is specifically designed for tool storage, assembly, presetting and management. The tool management system is complemented by the TRM software solutions for centralised management of machine and tool data, and WinTool for integrated tool and data management.