automation Dock

Automated loading/onloading platform for tool handling

The Automation Dock can be used flexibly in mechanical manufacturing: Whether loading/unloading

- a fully automatic presetting device (e. g. VIO linear)

- a fully automatic balancing machine (e. g. TD Preset Automatic Drive)

- a HAIMER Automation Cube

- a machining center

HAIMER Automation Dock offers maximum flexibility and stability in a modern, automated manufacturing environment.

Produce (or have produced) autonomously

The Automation Dock is a step towards 24/7 lights-out production

Features

- Flexible electric grippers from Zimmer that can handle various spindle interfaces

- Siemens TIA control

- Securing of the work area via safety laser scanner

- Flexible processing of up to 108 tools on one pallet

- Integrated NOK tray for ejecting tools

- Fully automatic communication and loading with AMR possible

- Media supply via electricity only, no pneumatic connection required

- Optional flexible connection to customer tool database possible (e. g. HAIMER Tool Room Manager or WinTool)

- Optional manual loading via pallet truck also possible for entry-level applications (scalable for more automation)

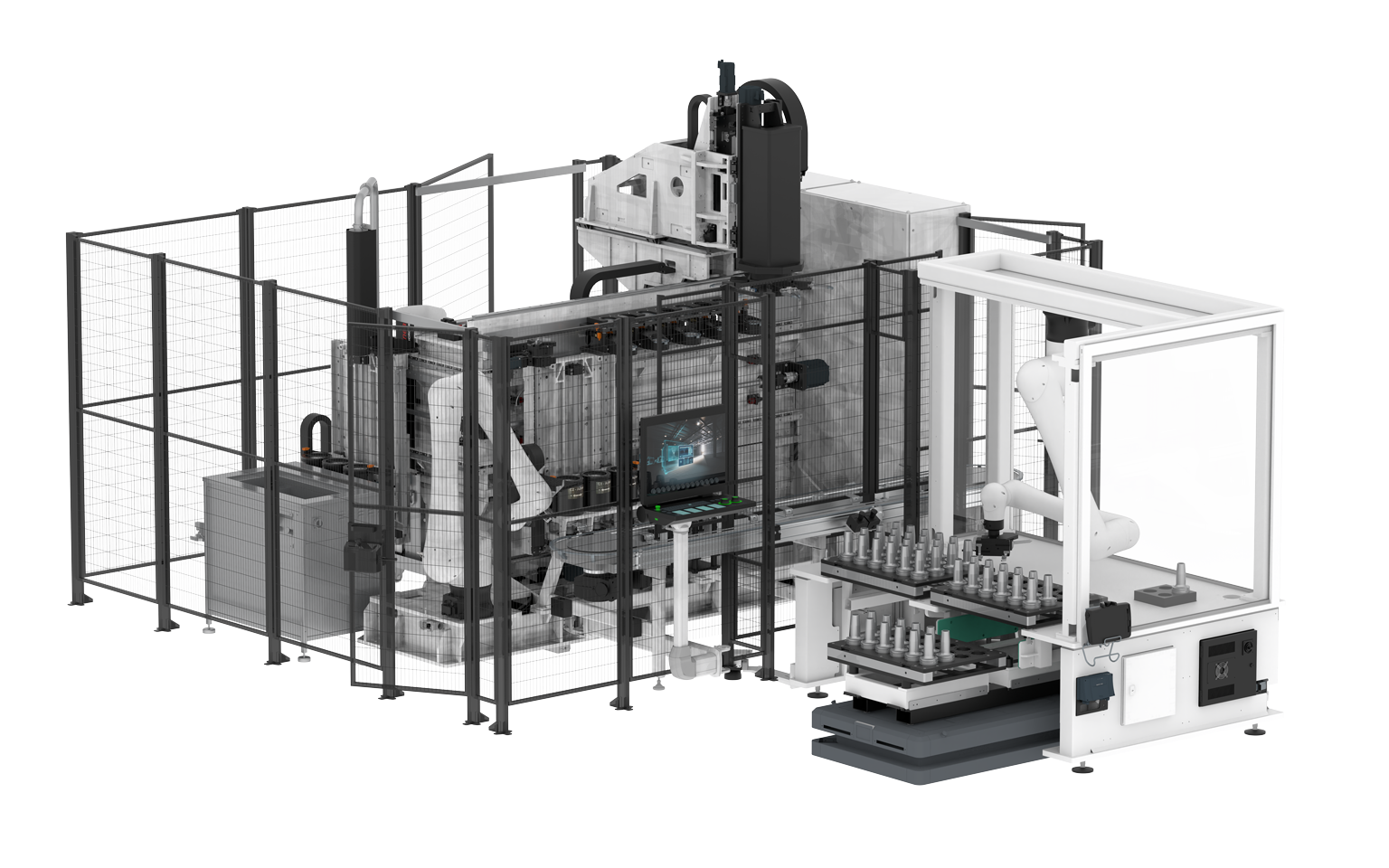

Sample floor plan

Loading the Automation Cube One

In the floor plan example shown, an autonomous mobile robot (AMR) works together with the HAIMER Automation Dock to perform fully automatic loading of the HAIMER Automation Cube One. The AMR moves independently within the production environment and performs material transport tasks - for example, supplying the machine tool with tool holders.

The integrated smart cobot of the Automation Dock takes the tool holders from the AMR and loads the Automation Cube One completely autonomously. In the further course of the process, the cobot continuously unloads the Automation Cube One and transfers the prepared complete tools to the AMR for further transport.

Automation Dock

The automated loading/onloading platform for tool handling.

Automation at HAIMER

From automated tool preparation and autonomous changing processes to smart connectivity with machines and systems, HAIMER paves the way for lights-out production. This creates intelligent manufacturing environments that increase productivity while ensuring maximum precision.

Our project partners

We would like to express our sincere thanks to our project partners for their valuable support in developing the Automation Dock. Their expertise, constructive feedback and close cooperation enabled us to successfully bring the project to market maturity. Thank you very much for your trust and strong partnership.

This may also interest you

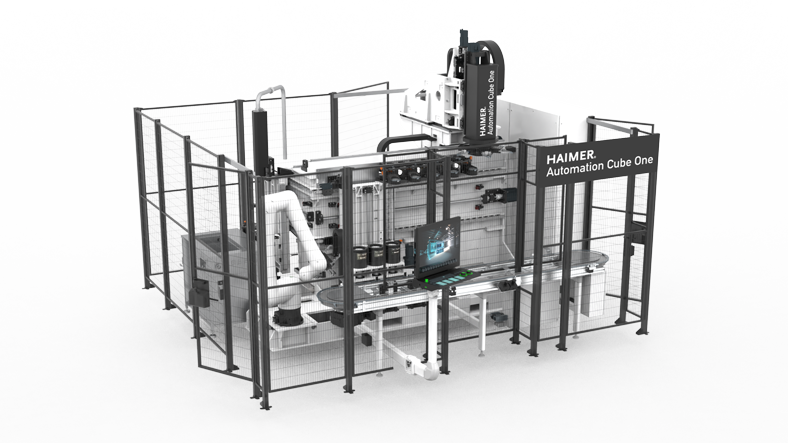

Automation Cube One

Automated Shrinking and Presetting Cell with Cobot and 12 Axis

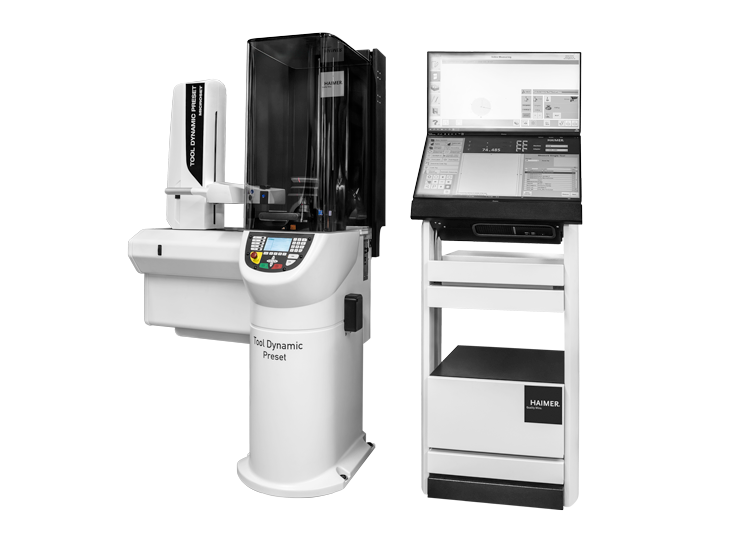

VIO linear

The complete solution: for fully automatic high-end tool presetting with customisable options.

Tool holder cart

The tool cart offers a standardized basic version with rollers, brakes, and handles, as well as flexible customization through a modular system.